Recently, a vacuum packaging production line built by Iapack for a customer successfully completed installation and commissioning, and passed the customer's acceptance! This project marks another important breakthrough for IAPACK in the application of high-speed vacuum packaging technology.

On-site report: efficient and stable, highly recognized by customers

At the acceptance site, the customer's technical team spoke highly of the equipment's operating efficiency, stability, and ease of operation. "The equipment runs smoothly, which completely solved our previous problem of low packaging efficiency." - The customer's on-site person in charge of production.

IAPACK fully automatic vacuum packaging machine operates efficiently at the production site

https://www.youtube.com/watch?v=I2OlNZH0DOE

Core Technology Highlights

The high-speed intelligent vacuum packaging machine accepted for this inspection integrates several innovative Iapack technologies:

1. Fully automatic high-speed packaging: Maximum speeds of 20-40 packages per minute significantly improve production efficiency;

2. Adaptive packaging system: Automatically adjusts packaging parameters based on product packaging size, enabling flexible production;

3. Intelligent visual inspection: Equipped with a high-precision vision system, it ensures the packaging quality of each product。

Wide Range of Applications

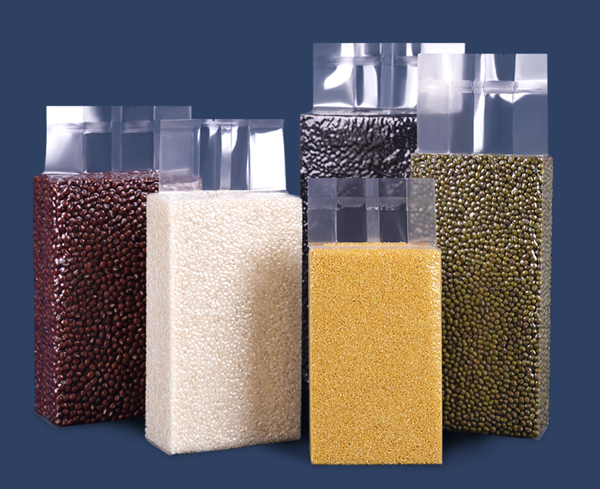

This series of packaging machines can be used in a wide range of applications:

· Vacuum bagging of food products, such as dry yeast, coffee powder, maltodextrin, powdered food additives, and various bio-enzyme preparations.

· Vertical vacuum packaging of food products, such as cornmeal, grains, and beans.

IAPACK consistently strives to create value for our customers through technological innovation. The successful acceptance of this project further demonstrates our leadership in intelligent packaging solutions. We look forward to providing efficient and reliable packaging equipment and solutions to customers in more industries, helping them achieve transformation and upgrades to intelligent manufacturing.